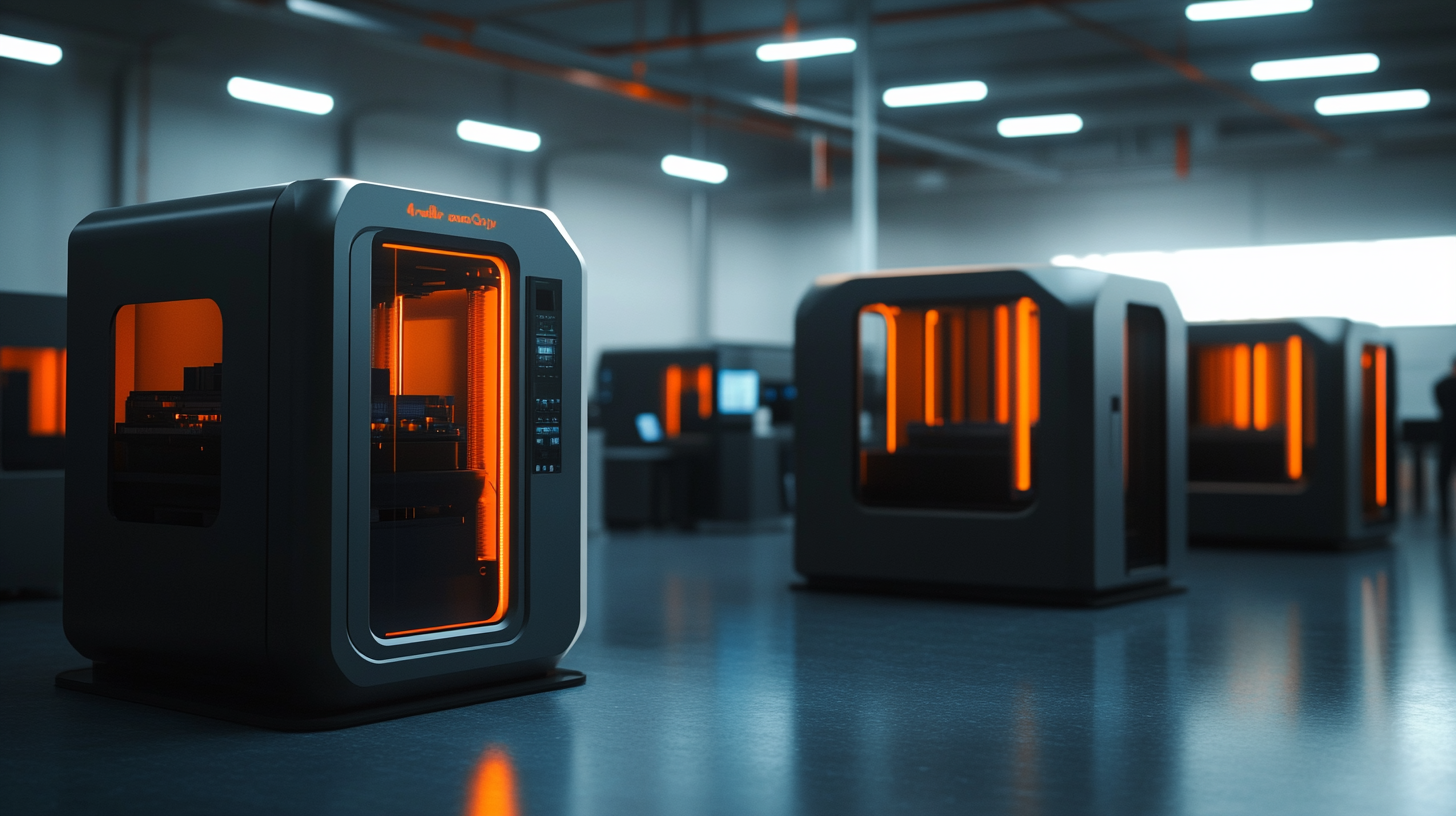

Finding Reliable Vendors for Large 3D Printers to Boost Your Manufacturing Efficiency

In today's fast-paced manufacturing landscape, the adoption of advanced technologies has become crucial for businesses aiming to enhance their operational efficiency. One of the most promising innovations is the large 3D printer, which enables manufacturers to produce complex designs and components at an unprecedented scale. However, as this technology continues to evolve, finding reliable vendors that provide high-quality large 3D printers is paramount to ensure sustained productivity and cost-effectiveness. With a multitude of options available, navigating the vendor landscape can be a daunting task, especially for companies looking to integrate this technology into their existing workflows effectively.

The right large 3D printer can not only streamline production processes but also lead to significant reductions in time and material waste. Therefore, it is essential for businesses to conduct thorough research and vet potential suppliers carefully. This blog will explore the key factors to consider when selecting a vendor for large 3D printers, from assessing product quality and customer support to understanding technological capabilities and industry reputation. By making informed decisions in choosing a reliable vendor, manufacturers can unlock the full potential of large 3D printing, ultimately driving innovation and competitive advantage in their respective industries.

Understanding the Importance of Reliable Vendors in 3D Printing

In the rapidly evolving landscape of 3D printing, the significance of partnering with reliable vendors cannot be overstated. As manufacturers seek to enhance efficiency and productivity, the selection of dependable suppliers for large 3D printers becomes paramount. Reliable vendors not only provide access to state-of-the-art machinery but also ensure continuous support and maintenance, which are crucial for minimizing downtime in production. The recent developments in the 3D printing industry highlight the need for strategic partnerships. For instance, collaborations between key players are reshaping the market and enabling providers to offer more customized solutions that cater to specific manufacturing needs. This trend underscores the importance of forming alliances with vendors who exhibit innovation and a deep understanding of market dynamics. By aligning with such partners, businesses can leverage advanced technologies that adapt to changing demands while maintaining a competitive edge. Moreover, as the market for 3D printing continues to expand, characterized by diverse applications ranging from customized toys to intricate medical devices, the role of reliable vendors becomes even more critical. These partnerships can foster a more agile production environment, enabling manufacturers to respond swiftly to market trends and customer specifications. Investing in trustworthy vendor relationships is not merely a strategic move; it is essential for sustaining growth and enhancing overall manufacturing efficiency in an increasingly competitive arena.

Key Factors to Evaluate When Choosing a 3D Printer Vendor

Choosing the right vendor for large 3D printers can significantly impact manufacturing efficiency, especially as industries increasingly pivot towards advanced manufacturing technologies. As evidenced by the recent news about the rapid growth in the global 3D printing metal market, it is essential to evaluate vendors based on specific factors that will ensure they meet your unique manufacturing needs.

One critical factor to consider is the vendor's expertise and experience within the specific vertical market, such as aerospace, healthcare, or automotive. For instance, Spain's recent establishment of a dedicated additive manufacturing center for defense applications highlights the importance of specialized knowledge and compliance with industry standards. When selecting a vendor, validate their past projects and client testimonials to gauge their proficiency in these targeted areas.

Another key evaluation criterion is the range of materials and technologies they offer. With emerging trends in metal 3D printing, including solutions from major players like HP, which recently introduced the Metal Jet S100 for mass production, it is vital to partner with a vendor that can provide diverse options. Assessing whether the vendor has an innovative approach to material science can also determine their capability to adapt to evolving manufacturing processes and product requirements. By focusing on these factors, businesses can optimize their 3D printing investments and enhance overall operational efficiency.

Top Vendors in the Large 3D Printer Market: A Comparative Analysis

In the expanding landscape of 3D printing, the large printer segment is poised for remarkable growth, projected to increase significantly in market value from USD 25,095.58 million between 2022 and 2027, according to Technavio. As manufacturing industries seek to enhance efficiency and reduce costs, identifying reliable vendors becomes critical. A comparative analysis of leading vendors in the large 3D printer market can serve as a valuable resource for businesses looking to make informed decisions.

Key players in this market offer a range of features tailored to various industrial applications. For instance, when evaluating vendors, it's essential to consider not only the printer's capabilities but also customer support, software compatibility, and the availability of materials that align with specific manufacturing needs. Companies focusing on sustainability may also prefer vendors that prioritize environmentally friendly practices, particularly in large-scale construction, where 3D printing can significantly reduce waste compared to traditional methods.

Moreover, recent studies suggest that large-scale 3D printing can lower environmental impacts when implemented thoughtfully, particularly in the context of construction, making it imperative for manufacturers to choose vendors who demonstrate a commitment to sustainable practices. In this evolving market, conducting a thorough comparative analysis of potential vendors can help businesses improve their manufacturing efficiency while aligning with broader sustainability goals.

Building Strong Relationships with Your 3D Printer Suppliers

Building strong relationships with your 3D printer suppliers is crucial for enhancing manufacturing efficiency, especially in the rapidly evolving field of additive manufacturing. The industry is projected to witness significant growth, with a burgeoning market that is estimated to expand at an annual rate of over 25% through 2033. This growth is driven by increasing demand for personalized and complex products across various sectors, prompting manufacturers to seek reliable vendors who can meet these needs.

Recent collaborations in the industry highlight the importance of strategic partnerships. For instance, one company announced a strategic alliance with a leading 3D technology provider to deliver high-value products in emerging markets. Such partnerships not only enhance product offerings but also improve service delivery, which is essential for manufacturers aiming to stay competitive.

Additionally, innovations such as open-source 3D printing solutions are redefining cost structures and accessibility within the market. A new model has emerged with a production cost of just $413, paving the way for smaller companies to enter the field. This democratization of technology emphasizes the need for manufacturers to nurture relationships with suppliers who are at the forefront of these advancements, ensuring they have access to the best tools and resources.

As the 3D printing landscape continues to transform, investing time and effort into building strong supplier relationships will be key to leveraging these opportunities for enhanced efficiency and innovation in manufacturing.

Strategies to Ensure Continuous Support and Maintenance for 3D Equipment

When investing in large 3D printers to enhance manufacturing efficiency, choosing reliable vendors is crucial, not only for the acquisition of technology but also for ensuring continuous support and maintenance. According to a 2022 report by Smartech Analysis, the global 3D printing market is expected to reach $41 billion by 2026, demonstrating a growing reliance on 3D technology across various industries. This growth underscores the importance of selecting vendors who provide robust ongoing support to maximize the return on investment.

To ensure continuous support and maintenance for your 3D equipment, it's essential to evaluate vendors based on their service history and customer satisfaction ratings. A comprehensive survey conducted by Wohlers Associates revealed that 58% of companies experience significant downtime due to inadequate support from their vendors. Therefore, prioritizing vendors with strong maintenance programs, such as proactive monitoring and on-site repairs, can mitigate downtime and enhance productivity.

Additionally, it's beneficial to choose vendors that offer educational resources and training programs as part of their ongoing support services. A study from the Support Industry Association indicates that companies that invest in employee training see a 35% improvement in operational efficiency. By fostering a partnership with vendors who prioritize training and development, manufacturers can ensure their teams are well-equipped to handle equipment issues promptly, further enhancing the reliability of their 3D printing operations.